FAN RENEWAL AND RETROFITTING PROJECTS

Why is Retrofit Work Performed on Fans?

- Achieving Energy Savings by Increasing Fan Efficiency

- Saving Energy with the Right Operating Point

- To Prevent Vibration, Increase Due to Powder Adhesion

- Reducing Stoppages Due to Dust Sticking

- To prevent rapid wear on the Impeller (Rotor) and Volute

- Eliminating Capacity Inadequacy

- Modernization and renewal of existing fans with low investment cost

- Extending product service life

- Reduction of noise level

- Ensuring increase in production volume

- Reduction of Operating and Maintenance costs

- Ensuring compliance with legal requirements

Stages of Fan Retrofit

Decision for a Complete Fan or Only Rotor Design

To decide whether a new rotor can be designed inside of existing casing

Existing casing evaluated considering new rotor design based on requested capacity values.

If casing condition is in compliance, only rotor gets designed. If not, complete fan offered

New Rotor & Fan Design Stage

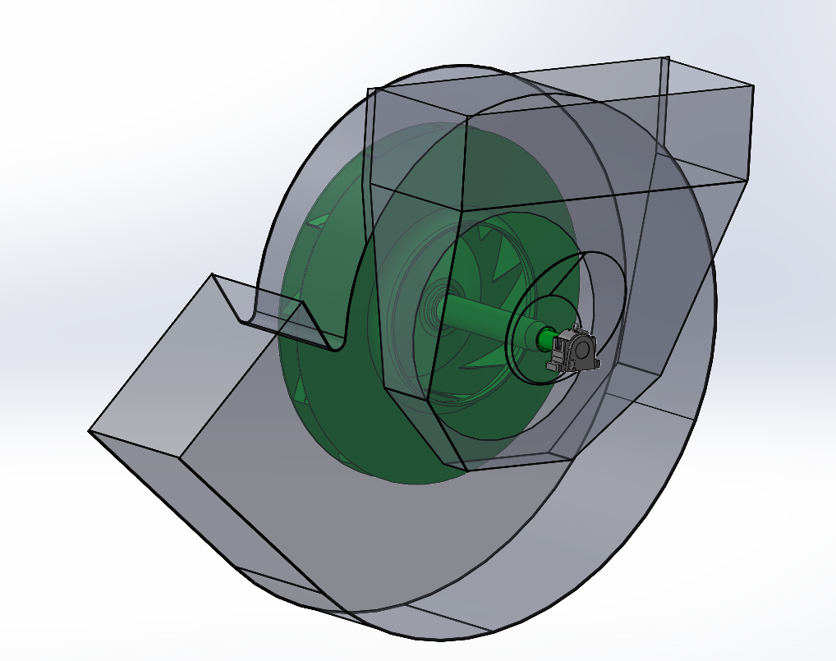

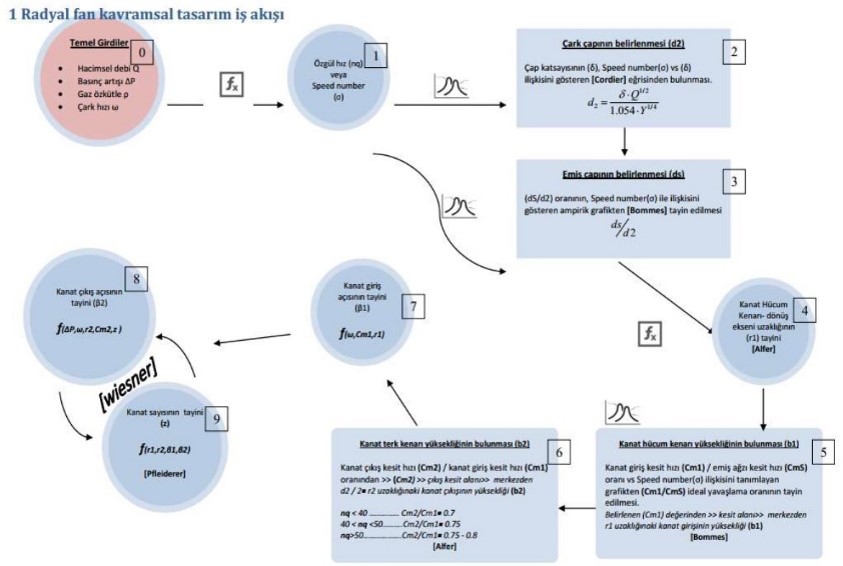

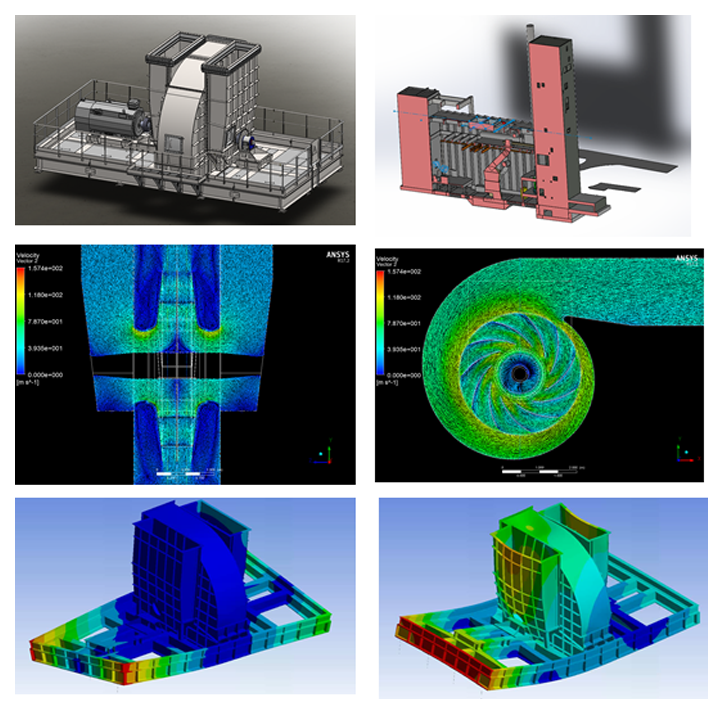

Conceptual Design

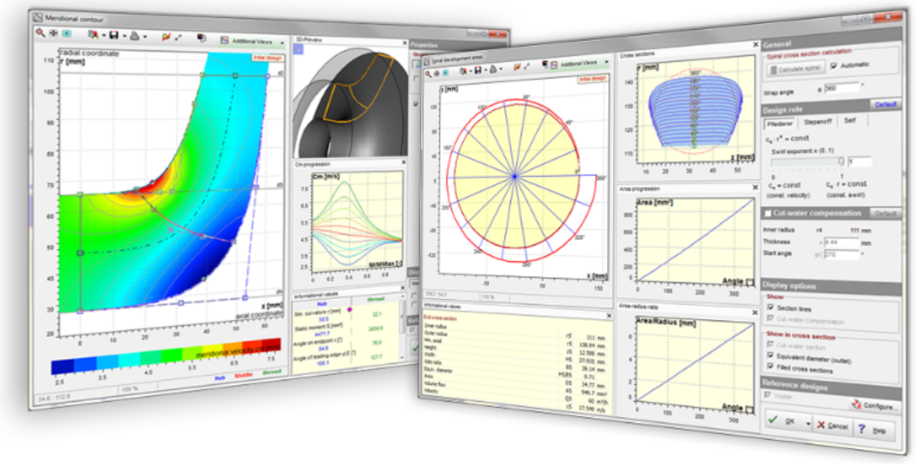

With ALFER's design correlations interactive fan design software

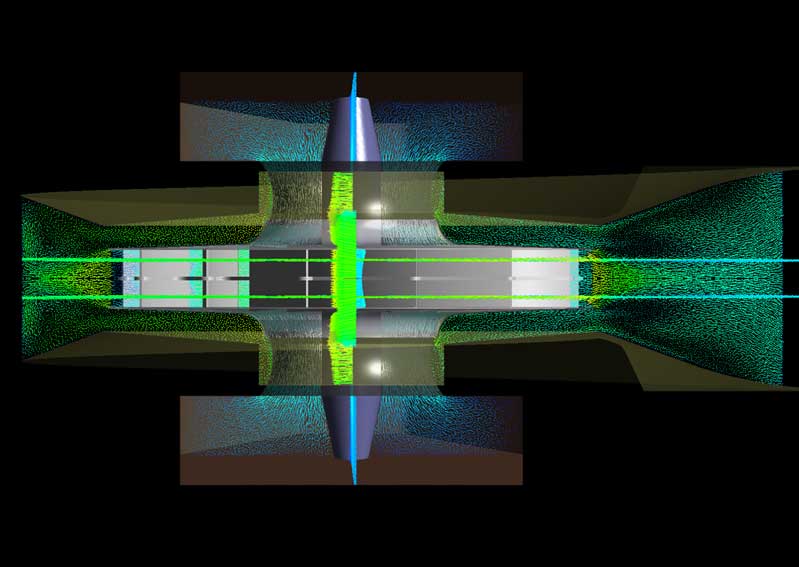

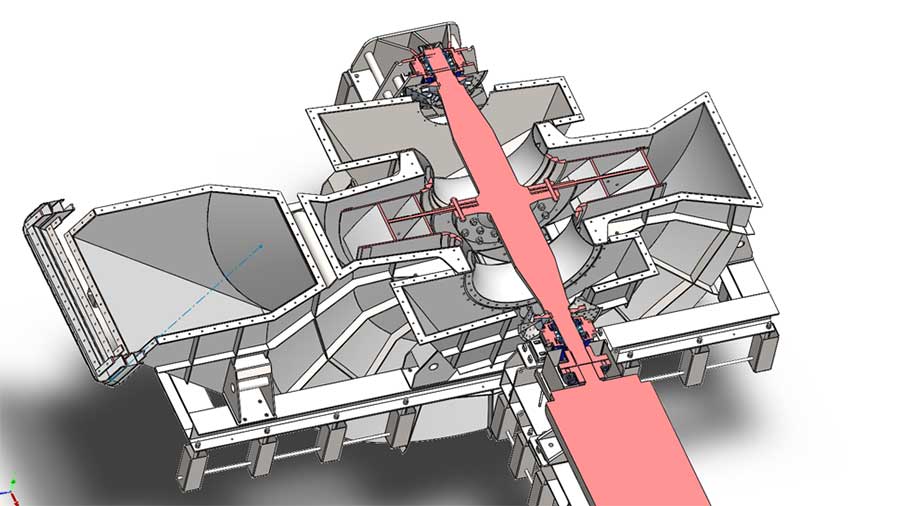

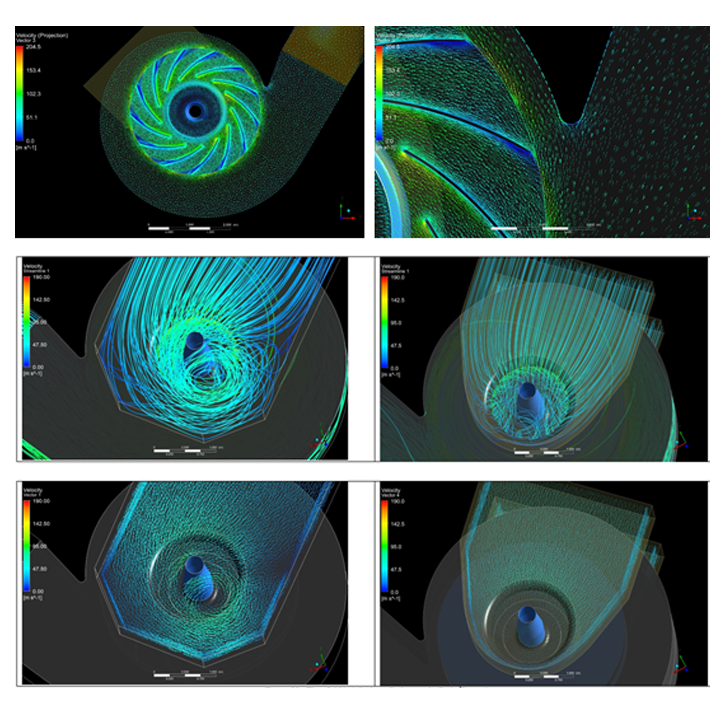

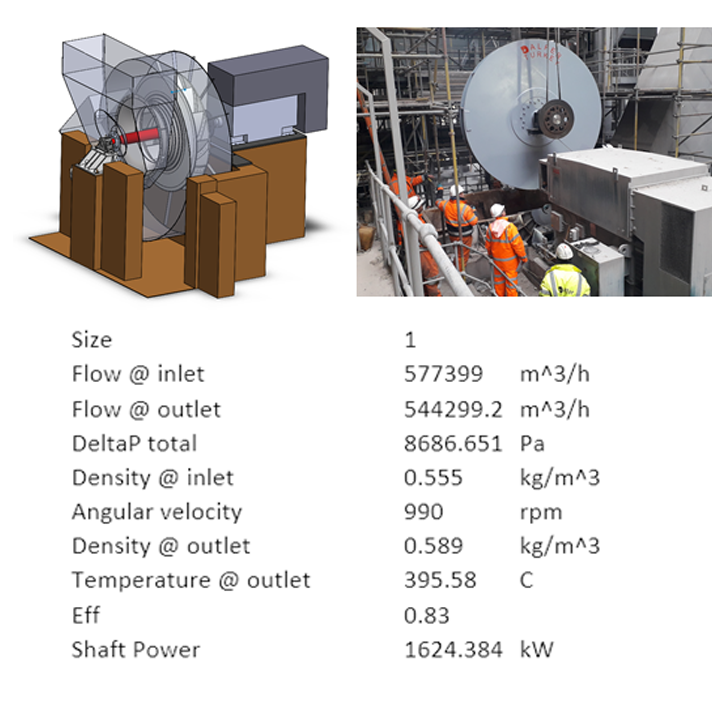

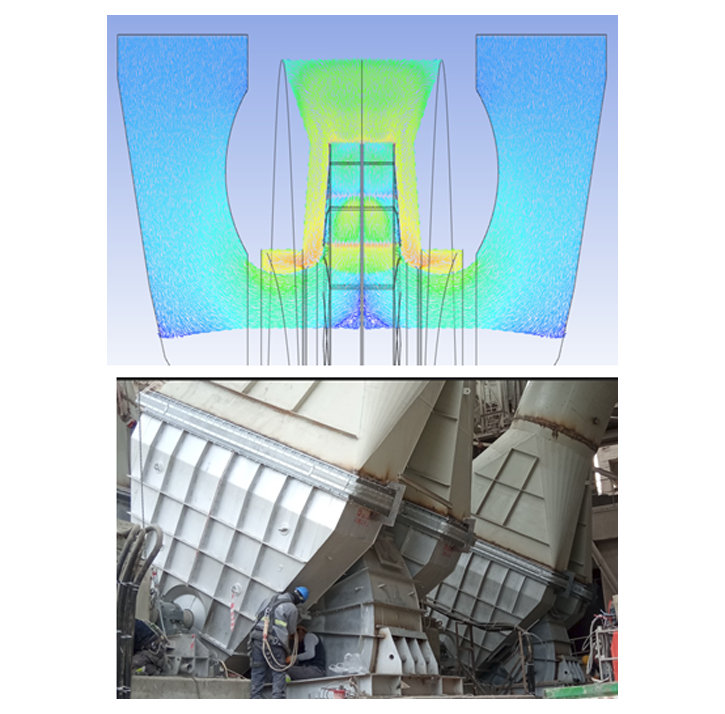

Aerodynamic Design / CFD / Capacity and Flow Control

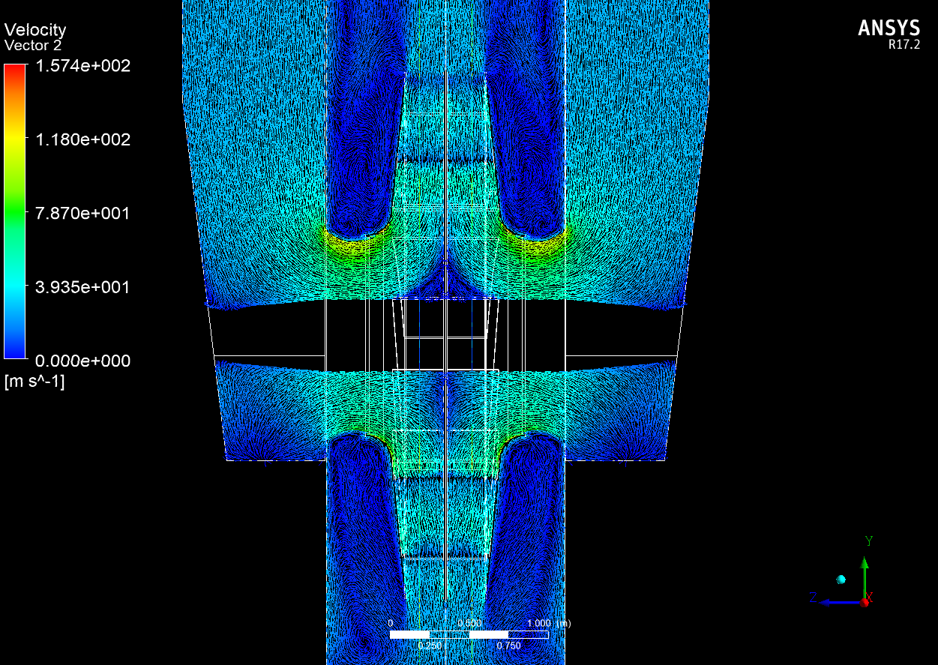

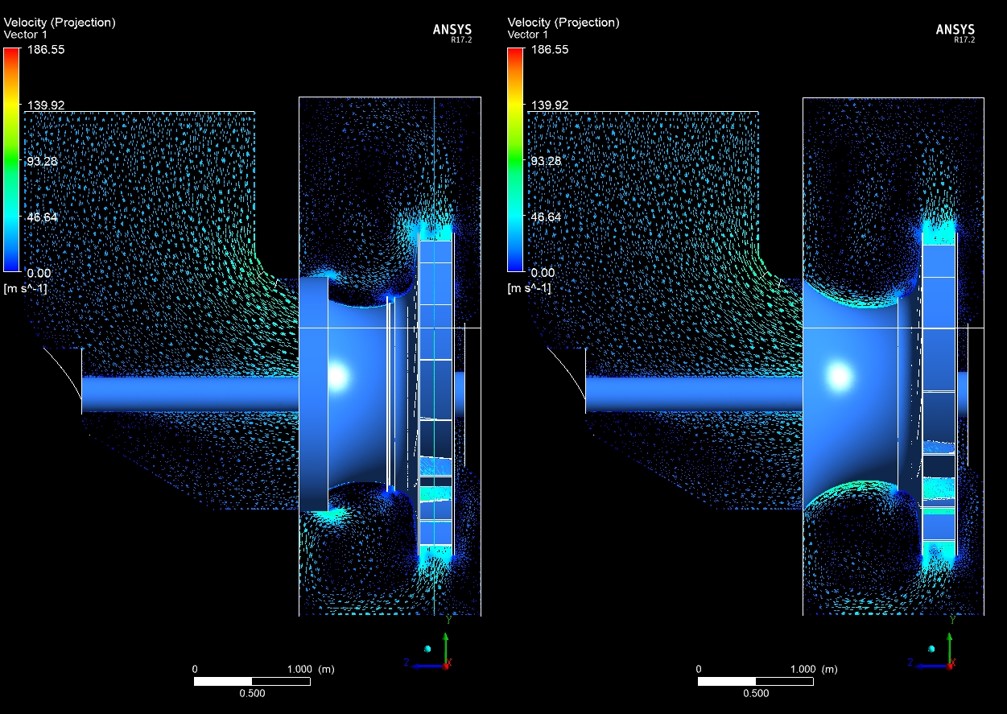

Flow of the Inlet Box and fan casing

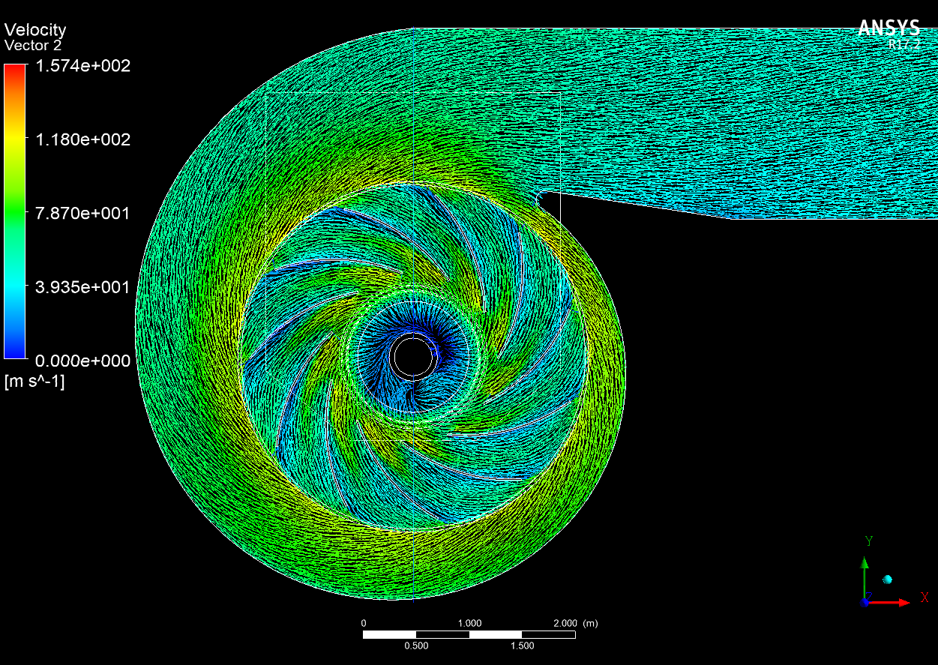

Flow of the blade passage and casing

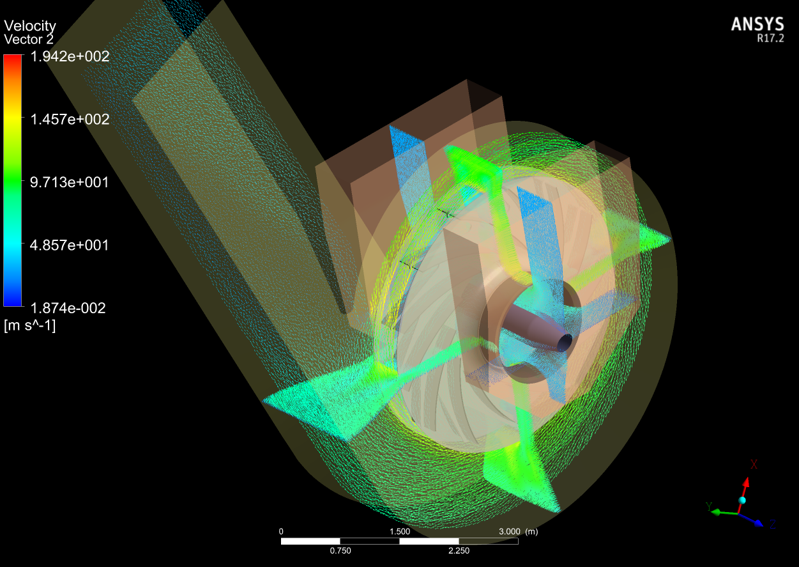

Aerodynamic Design / CFD Analysis

Fan CFD Analyses / Velocitydistrubition

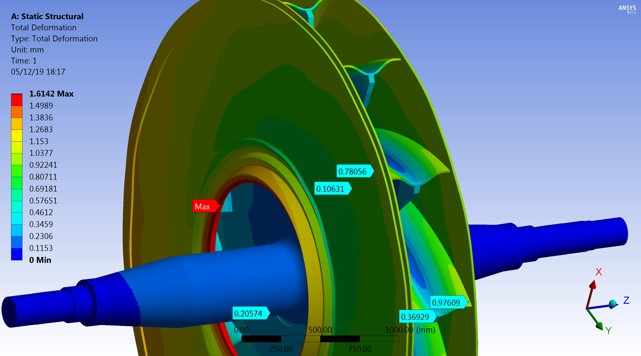

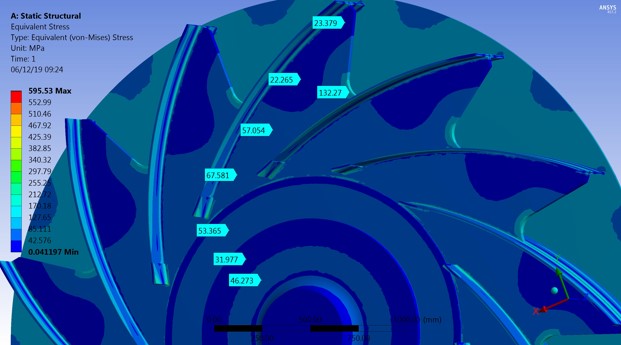

Mechanical Design / Stress & Deflection Control

Max. 425 Mpa (990 rpm)

Max 1,6 mm (990 rpm)

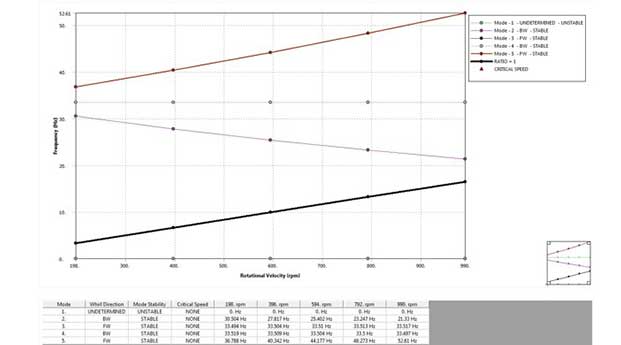

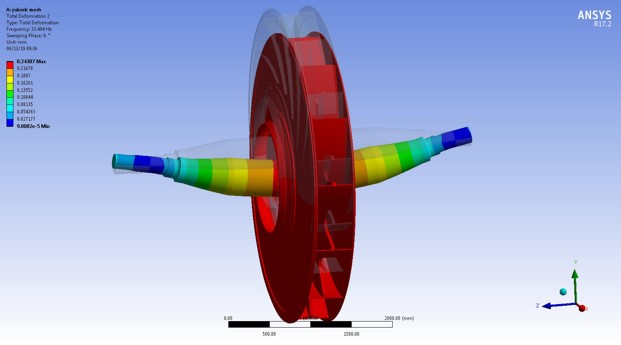

Mechanical Design / Resonance Control

1 mod 29,50 Hz (1770 rpm)

2 mod 39.05 Hz (2343 rpm)

8 mod 22,43 Hz (1345 rpm)

7 mod 20.53 Hz (1231 rpm)

Retrofit Fan Design Example

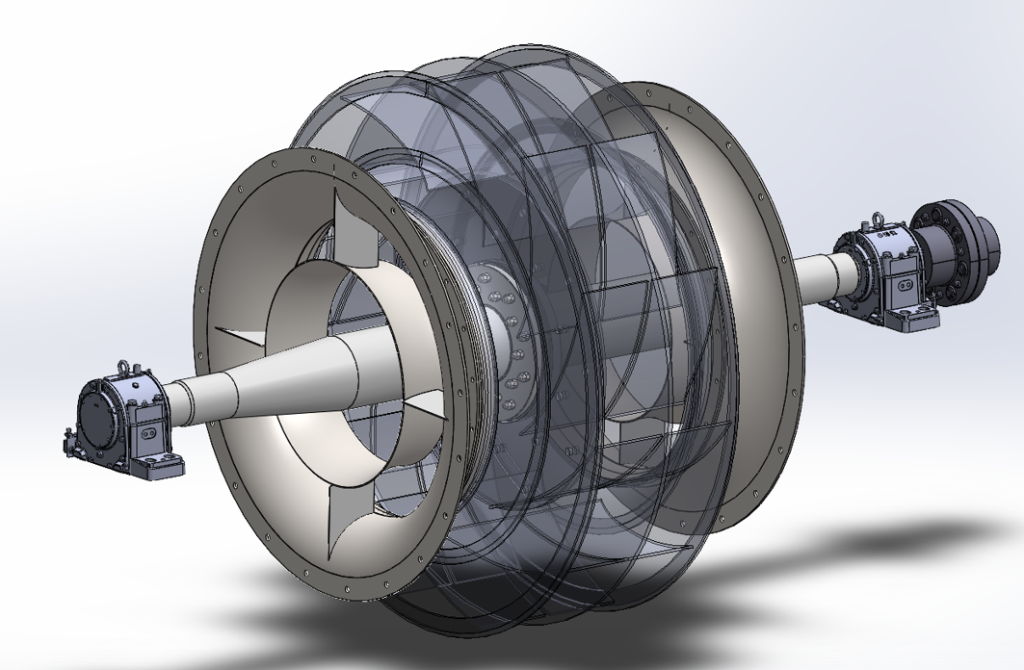

Low Specific Speed (nq24) Kiln ID Fan

Definition of the Problem ?

- Vibration increase Due to Dust Accumulation

- Downtime every single month

- Loss of Production

- Decreasing lifetime of bearing housing and bearing units

Solution? First Step

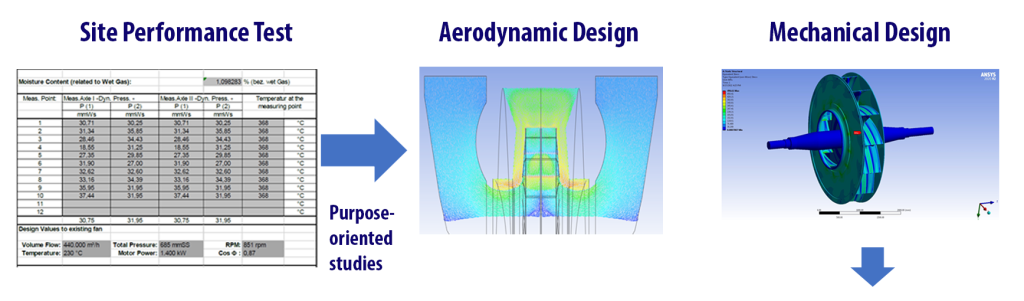

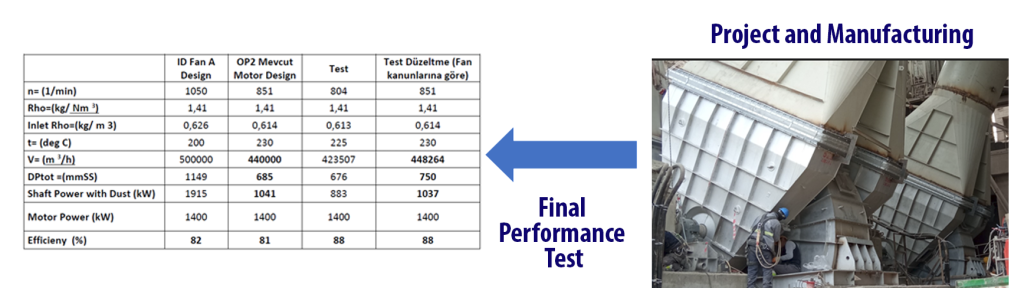

- Conducting fan performance test at site and defining existing operation values

- Defining New Operation Point

- Tailor Made Fan Design Considering specific Issue

What are the Precautions in the new design ?

- Total Flow Surface Optimization by designing a star type Back Plate

- Defining a New Operation Point and Flow Optimization

- Changing Impeller Radius and Blade Passage Flow Optimization

- Blade Leading Edge Optimization for Specific Speed

- Design and optimization of the flow velocity distribution in the casing and impeller

- Prevention of Flow separation in casing and airborne dust in casing

- Increasing casing efficiency with Trapozoid shape casings

Aerodynamic Design / CFD Analysis

Mechanical Design/ Stress & Resonance Control

Project-Manufacturing- Assembly

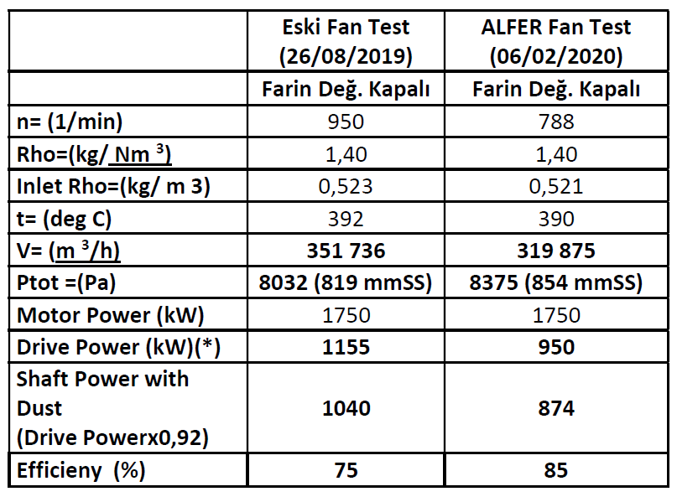

Result?

- Vibration level became extremely low

- Stoppage Time Due to Dust Accumulation is over

- 166 kWh %16 energy saving

Low specific speed/ Serbia Booster Fan Design

Possible Problem Occurrences?

- Low specific speed(Nq24)

- High Dust

- Long blades necessity

Result?

- No vibration due to dust adhesion.

- No dust related stoppage problems.

Raw Mill Filter Fan Rotor Design

Possible Problem Occurrences?

- Impeller for existing casing

- Capacity Increase

Results?

- Desired Capacity provided.

- Targeted efficieny achieved

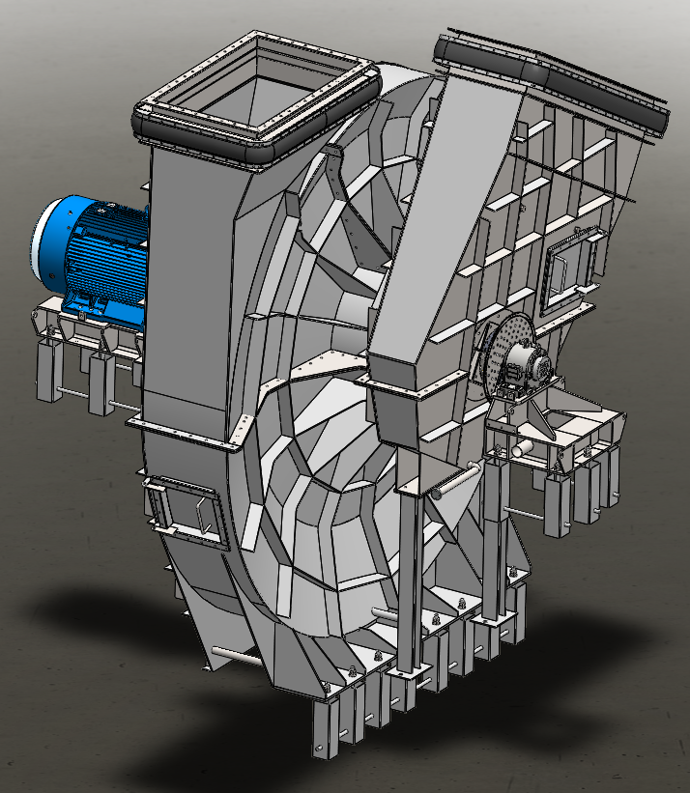

Raw Mill Filter Fan Design

Possible Problem Occurences ?

- Work on the Beams in the Intermediate Floor

- Low Intermediate Floor Height

- High Efficiency and Small Area

- The Resonance Problem of the Chassis on the Spring

Results?

- Capacity achieved.

- High Efficiency achieved

- No Vibration Problems

- No Resonance Issues

Klinker Cooler Filter Fan Rotor Design

Possible Problem Occurences ?

- Impeller for existing casing

- Requested Efficiency Increase

Results?

- High Efficiency achieved

- No vibration problems.

Kiln ID Fan Rotor Design

Possible Problem Occurrences ?

- Lack of Capacity Increasee

- Lack of Requested Efficiency

Results?

- Inlet Box Revision

- Requested capacity point reached.

- No Vibration Issue

- No Resonance Issue

Cement Ø3380 Kiln ID Fan Rotor

Possible Problem Occurrences?

- Existing conical fan casing shape

- Lack of Required Capacity

- Required High Efficiency

- High Temperature (460 C) durability issues

Results?

- Requested capacity achieved.

- No Vibration issue

- No Resonance Issue

- No mechanical problem from high temperature

Low specific speed (nq30) Kiln ID Fan Design

Possible Problem Occurences ?

- Required High Efficiency

- Different operation Point

- Long blades necessity

- Low specific Speed(Nq30)

- Dust accumulation

Results?

- High Efficiency provided

- No Vibration issue

- No Resonance Issue

- No dust related stoppage problems

Kiln ID Fan Dust Abrasion Analysis

Problem ?

- High Abrasion Rate