Why is Retrofit work done on filters?

- Ensuring uniform flow in the filter

- Reduction of filter operational pressure loss

- Less energy consumption

- Longer bag life

- Low equipment investment costs

- Low emission values

- To prevent dust accumulation and blockage formation in filters

- To prevent wear on the Filter Housing

- To prevent rapid wear on equipment such as fans, to extend the service life

- Modernization of equipment with minimum investment to meet the increase in production

Reducing the cost of Operation and Maintenance

The need for increased production and lower emission values creates the need to review, renew and strengthen existing dedusting systems. These modernization works can be done with technological solutions by providing significant savings with the cost-effective works we offer.

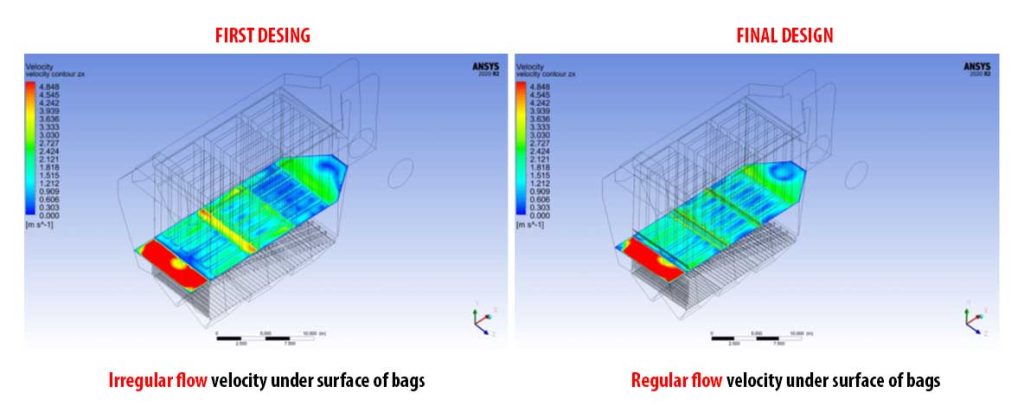

Non-uniform flow in the filter increases the filter operating pressure difference and increases the energy consumption of the filter fan after the filter. In addition, non-uniform flow patterns reduce the lifetime of expensive filter bags. By ensuring uniform flow distribution, less energy consumption and long bag life can be achieved.

Stages of Retrofit for Bag Filters

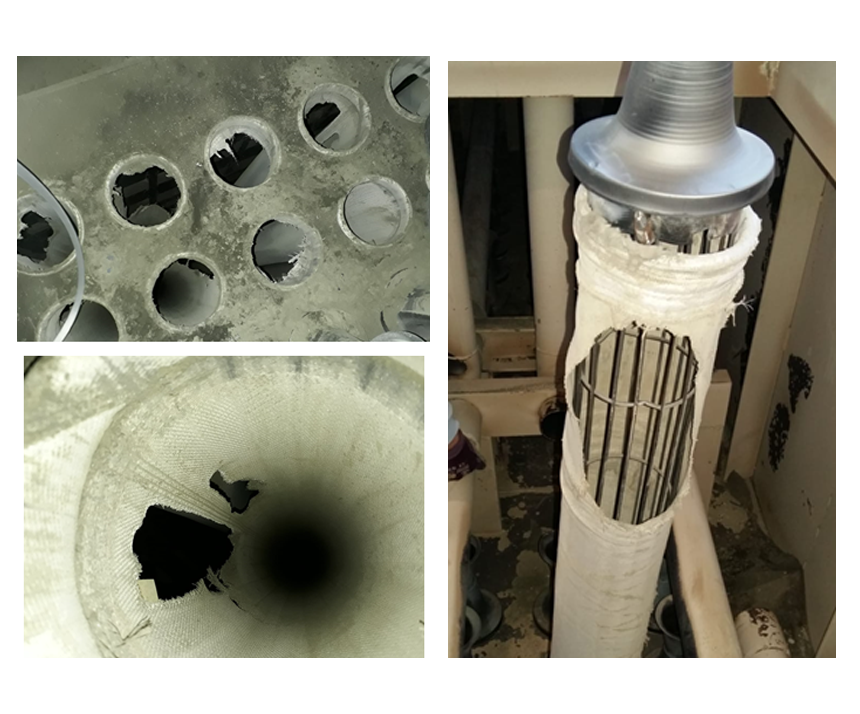

Filter Bag Failures

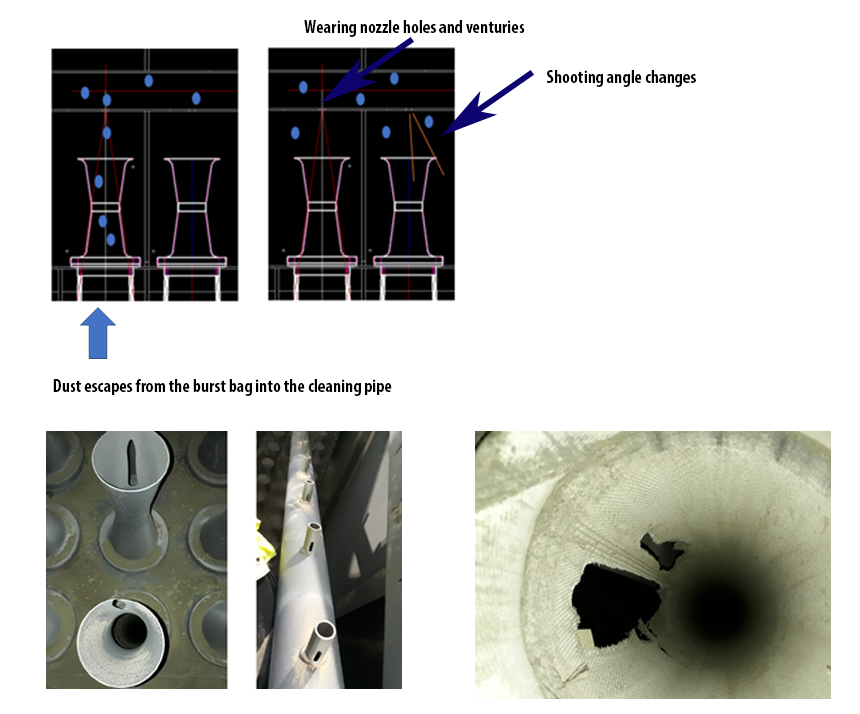

Burst Issue on the Bag at the top side

Problem

- Filter bags burst from the top side

Possible Cause of the Problem

- Centering problem of the Cleaning air nozzle

- There is dust in the cleaning side (top boxes)

- Abrasions on the cleaning pipe and nozzles

Possible Solutions

- Control the centering of the cleaning nozzles

- Replacement of cleaning pipe and nozzles

How does the problem occur

- Any single bag is burst

- Dust escapes from the burst bag into the cleaning pipes

- Nozzle holes and venturies are damages

- Shooting angle changes with dust abrasion

- Abrasive dust into cleaning pipe hits venturies

- After venturies damages many bags burst happen too fast

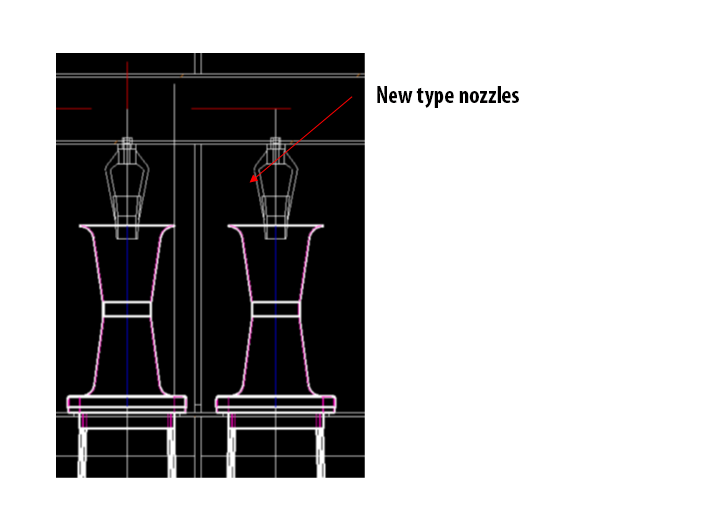

Solution

- Prevention of venturies damages with new easy-change nozzle

- Reducing bags bursting.

- Preventing the problem from occurring by using a burst bag detector

- Energy savings with reduced compressed air requirement

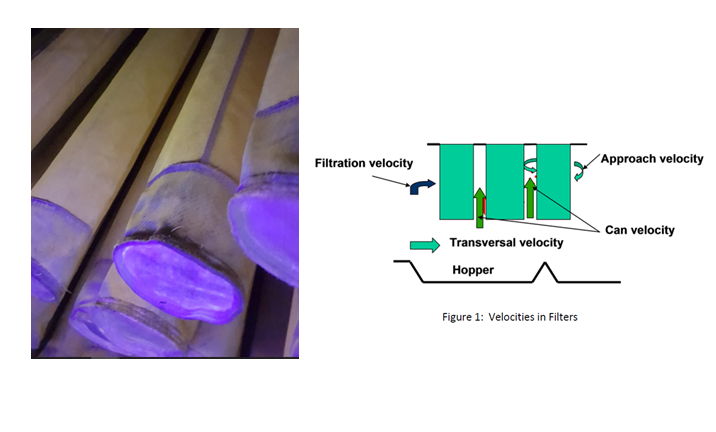

Burst Issue on the Bag at the bottom side & cylindrical side

Problem

- Filter bags burst from the bottom side & cylindrical side

Possible Causes of the Problem

- Poor filter design

- High can velocity

- High Approach Velocity

- High Transversal Velocity

- Poor flow distribution inside the filter

- Incorrect design of the filter inlet pipeline

Possible Solutions

- Cfd Analysis to find the cause of the bags burst

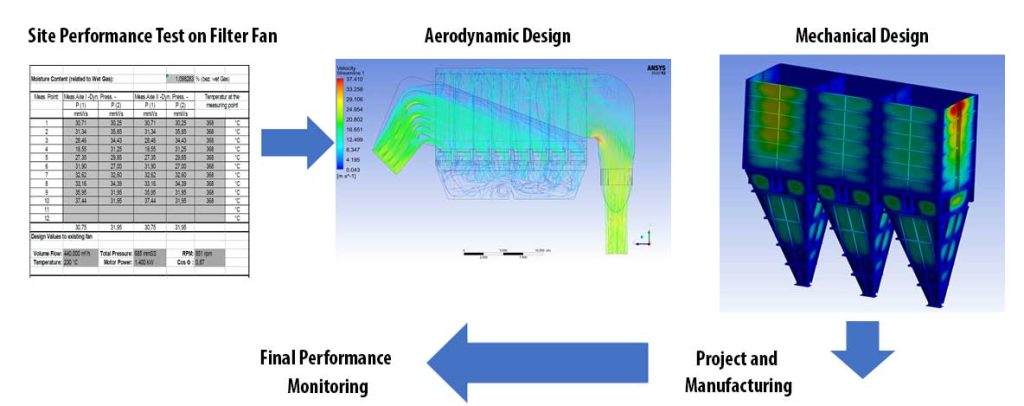

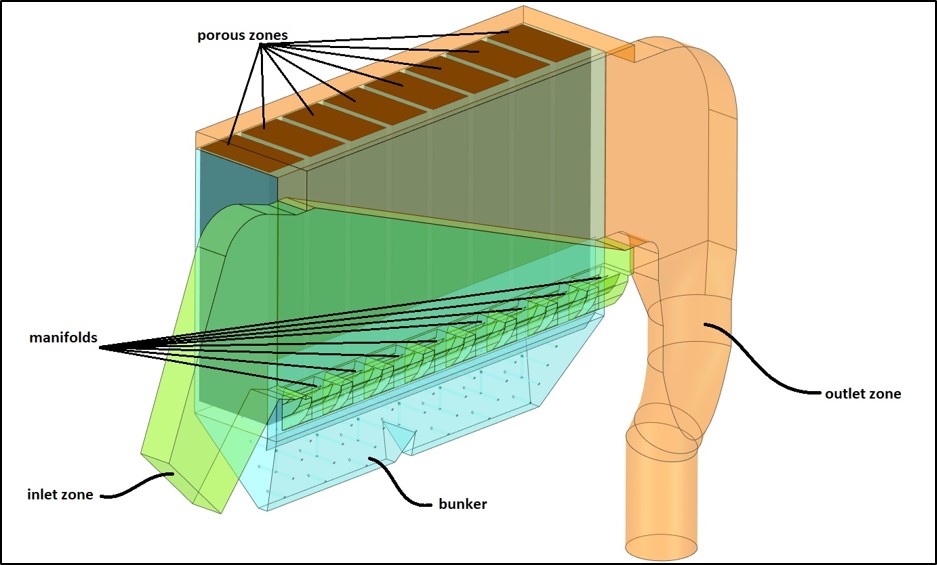

Retrofit Project Example on Bag Filter

Mill Process Bag Filter CFD Analyses &Flow Optimization

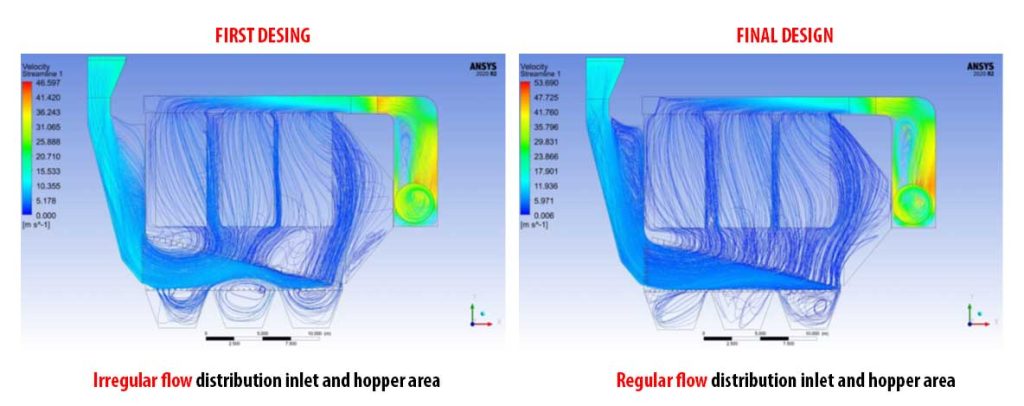

The aim of this study is to investigate the inlet region and inside of the filter flow.

Filter interior design should be done correctly.

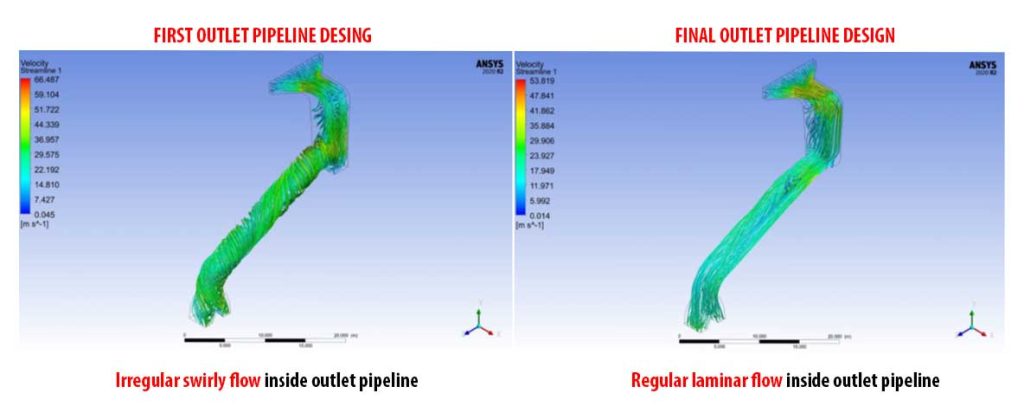

Inlet and outlet pipeline design is as important as the filter interior design. Because poor inlet pipeline design changes the filter performance.

Problems of the Poor Inlet Pipeline Design

- Irregular air flow in filter and some of the bags not working properly

- High energy consumption with increased system resistance

- Corrosion occurs on filters casing and bags in irregular flow areas

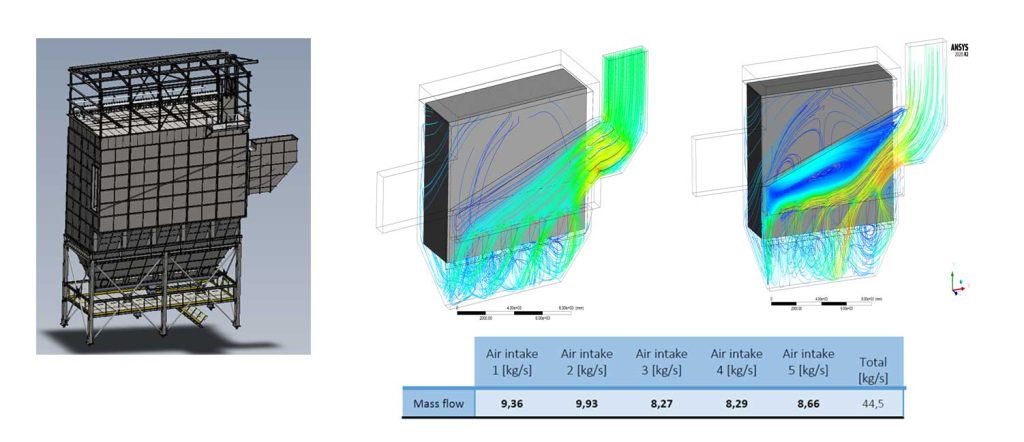

- Filter gas flow : 1.100.000 m3/h actual

- Gas density : 0,850 kg/m3

- Solver : ANSYS CFX

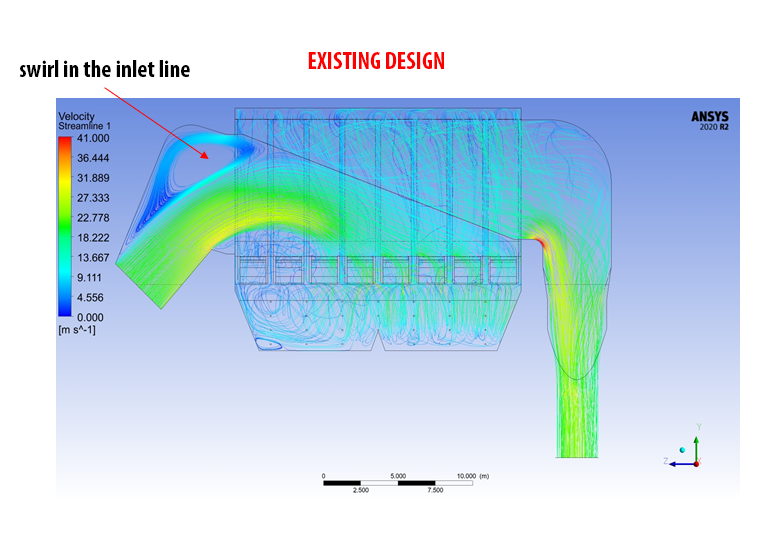

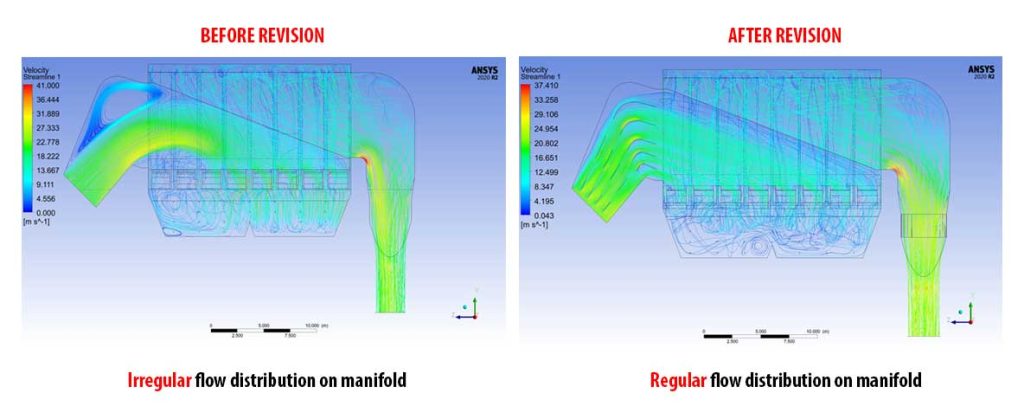

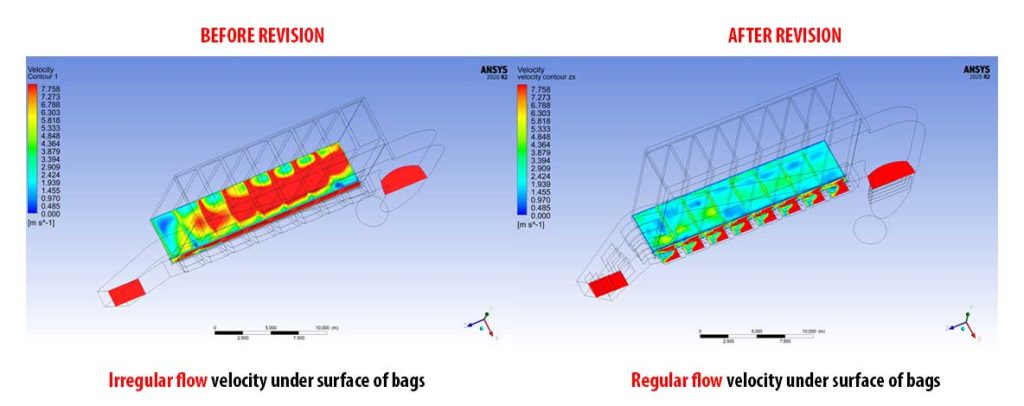

Existing Filter Design Problems

- Irregular air flow inlet pipeline

- Big swirl in filter inlet

- Irregular flow distribution on manifolds

- Big swirl in filter outlet and filter fan performance losses

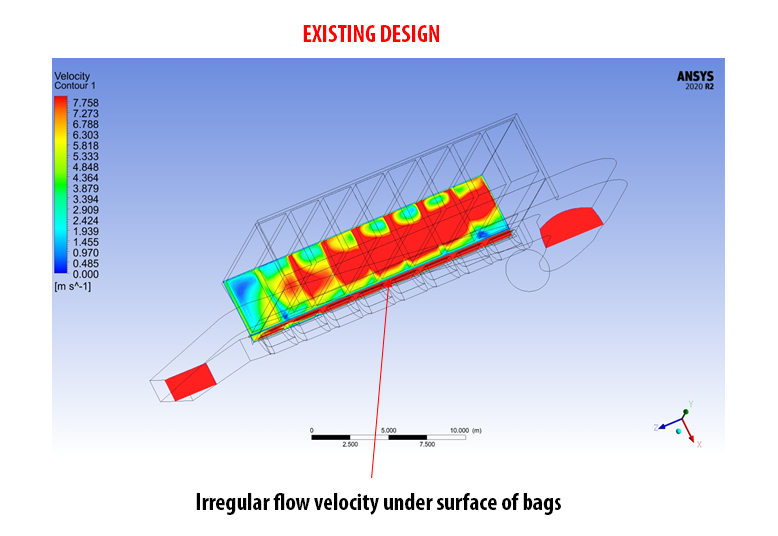

Existing Filter Design Problems

- Irregular flow velocity under surface of bags

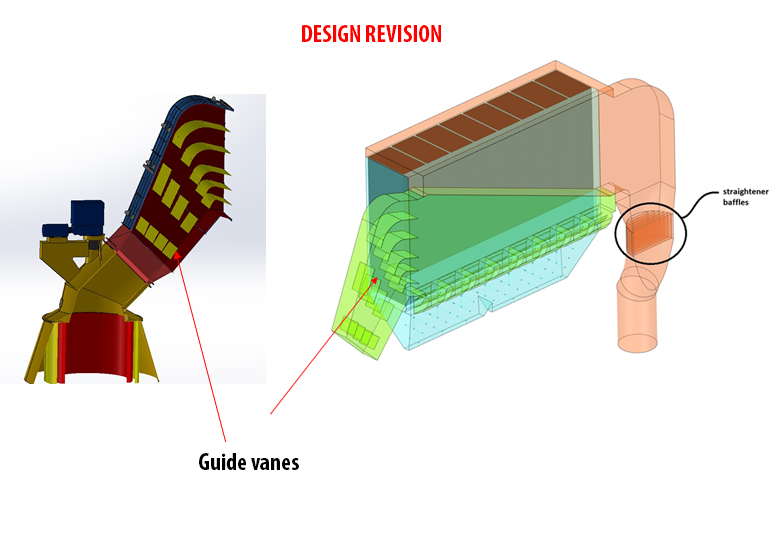

Design Revisions

- Guide vanes are added to the inlet ducting

- Straightener baffles are added in outlet section

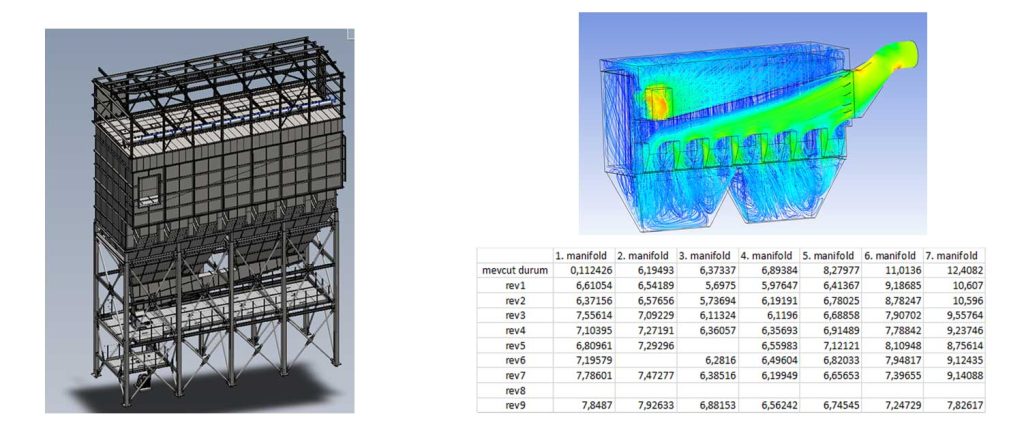

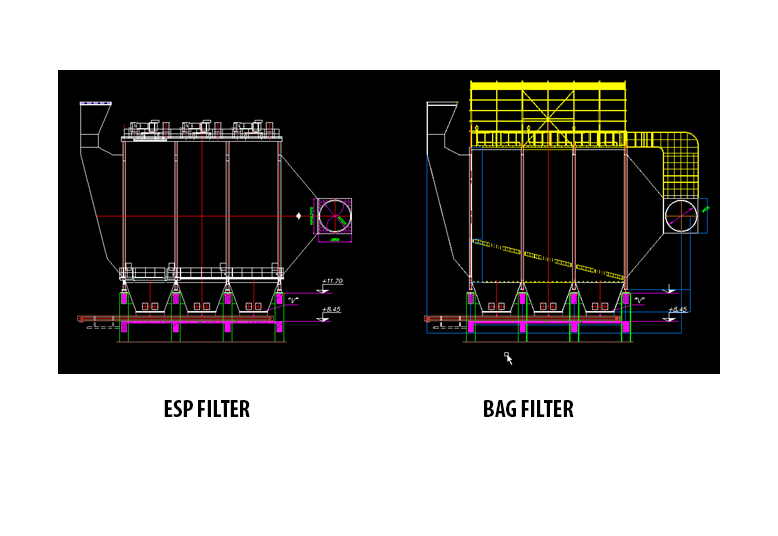

The aim of this study is to investigate the inlet line and inside of the converted bag filter flow.

Inlet and outlet design is as important as the filter interior design. Because poor inlet design changes the filter performance.

- Filter gas flow : 603 000 m3/h actual

- Gas density : 0,735 kg/m3

- Solver : ANSYS CFX

Fan performance loss is prevented by output pipeline correction ( Pleasesee AMCA 201-02 / System inlet effectclause)

Bag Filter structural analyses / Large deflection problem

Calsined Clay Jet Pulse Filter Flow Optimization